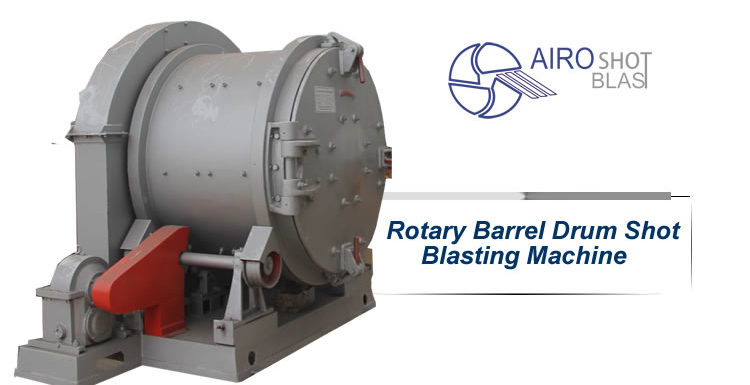

Drum Shot Blasting Specifications :

| Description | Model Airo RBF-1 | Model RBF-2 |

|---|---|---|

| Flow Rate of Wheel (Kg./Hr.) | 1135 | 6000 |

| Drum Size (mm) | 575 (Dia) X 625 (L) | 900 (Dia) x 950(L) |

| Barrel Capacity (Kg.) | 100 | 150 |

| Barrel Effective Volume (cft) | 1.5 | 3 |

| Loading Height (mm) | 370 | 370 |

| Type of Dust Collector | Fabric Bag | Fabric Bag |

| Dust Collector Capacity (cfm) | 400 | 1200 |

| Hp of Dust Collector | 1 | 3 |

| Total Power Requirement (HP) | 5 | 15 |

| Initial Charge of Abrasive (Kg.) | 35 | 200 |

| Abrasive Blast Cleaning Cycle | 15-20 Min. for Cast Iron | 15-20 Min. for Cast Iron |

Drum shot blasting machine clean by tumbling parts. Due to the type of process, this system covers a wide spectrum of needs, but we can say that in general it is recommended for any part which, due to its shape and material, can be tumbled. All tumbling machines can be easily combined into continuous manufacturing processes, with different dosing, loading, and unloading systems.

Working of Drum Shot Blasting Machine

The blasting process starts and lasts as long as the workpieces are mixed and blasted from all sides. The interior of the blasting cabinet is equipped with materials that are very resistant against abrasive media. The primary wearing in the direct blasting zone of the high-performance turbines is composed of high-resistant, replaceable steel plates. During the blasting process, the door keeps closed and could only be opened after the cabin has become dust-free. That takes around 10-15 sec. A slight low-pressure exhausts the dust during the blasting process. The dust will be separated into the appropriate filter unit.

After the blasting process the drum swings into the unloading place. At this position, it is also possible to determine the quantity of the workpieces and the intensity of unloading by using a dosed emptying. The treated workpieces arrive on a screen conveying trough which separates the residual abrasive and transports the pieces to forthcoming boxes.

Applications of Drum Shot Blasting Machine

- automotive industry

- Construction Industry

- Windpower Industry

- Railway Industry

- Foundry-Forging Industry

- Shipyards

- Shot peening

- Heat treatment

Drum Shot Blasting Machine Manufacturer

we are the best Drum Shot Blasting Machine & sand blasting machine Manufacturers & Supplier in Jodhpur, India. Their well-qualified and experienced team ensures clients’ satisfaction with consignments need special care during storage and packaging. They can help you to get the best fit particular and suitable Drum Shot Blasting Machine for best results & performance. Along with it, we have become the primary choice of companies for shot blasting machines and its abrasives also the best quality shot blasting machine safety equipment. we are leading shot blasting machine manufacturers in India at the best price.

Drum Shot Blasting Machine Price in India

our company provides shot blast equipment, peening machine, abrasive machine, and drum shot blast machine at the lowest prices with quality. Best deals and discounts are offered to clients as compared to other sellers in India.we have maintained excellent after-sales support. The cost of the product depends upon the ranges apart from it for rendering reliable services; we are backed by sincere experts, who hold rich knowledge and experience of the shot blasting industry.