HVOF reaches for High-Velocity Oxygen Fuel, and from its name, it is easy to understand that this thermal spray process has to do with using fluid materials at a high speed on substrates. HVOF thermal spray can supply many different coating properties for applications across different industries, and that reason the HVOF thermal spray process has converted one of the most widely utilized techniques to create dense coatings on various types of surfaces.

The high-velocity oxy-fuel process was created only 20 years ago, yet has thrust the thermal spray utilization scope into areas that were once unobtainable. In HVOF spraying, a mixture of process gases, such as hydrogen, oxygen, and air, is injected into the flaming chamber of the torch at high pressure and inflamed. The resulting gas velocities reach supersonic speeds. The powder is inserted into the flame and also accelerated to supersonic speed.

The HVOF process is the approved method for spraying wear and corrosion-resistant carbides as well as Hastelloy, Triaballoy and Inconel combinations. The coatings have high bond depths, fine as-sprayed surface finishes, and level of oxide is low.

Conveyor screws are used in power plants to move limestone into the boilers. The customer used a screw produced from carbon steel and is required to be replaced/repaired yearly due to the abrasion of the limestone. The thermal spray was to apply a thin layer of wear-resistant tungsten carbide on the shaft of the flights using the HVOF system. This repair procedure has increased the life of the screw.

Hovf gun latest price and specification:

| Material | Iron |

| Air Pressure | 70 – 100 psi |

| Nozzle Size | 3.15 mm |

| Wire Feeding | Pneumatic |

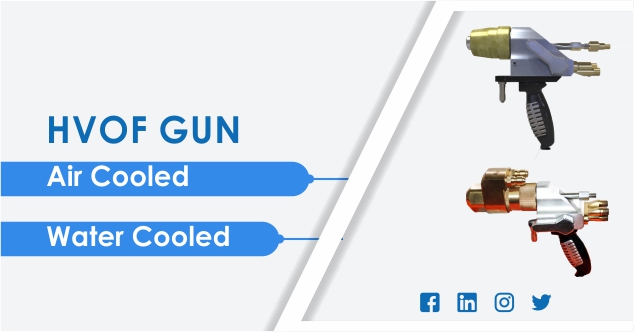

hovf gun latest price in India: Our affluent industrial knowledge helps us in presenting an extensive series of HVOF Thermal Spray Gun. Our products can also be customized as per necessities of our patrons.